RIPLEY TANKS ARE DESIGNED TO FIT YOUR NEEDS

Ripley fabricates custom brewery tanks built to your specifications and that are designed to maximize your floor space.

At Ripley we can supply complete brewery systems or individual component tanks built to normal brewery standards – depending on your needs.

Talk to us about your requirements and we will design a system to work for you and your company.

Contact us today.

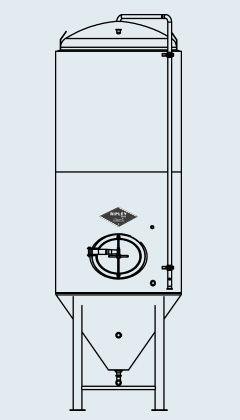

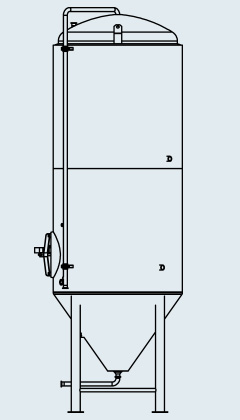

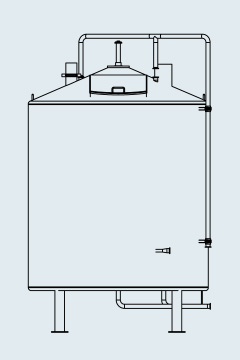

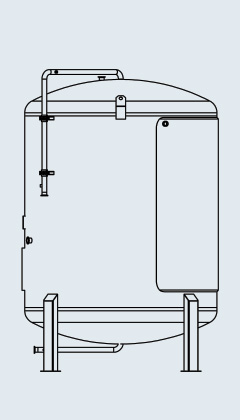

Fermentation Tank

Our fermentation tanks primarily act as a holding tank while the wort ferments. These tanks are made to your specifications.

| Dimensions | to be determined by RSL and customer |

| Capacity | Nominal capacity plus 25% |

| Top Head | ASME dished head (gauge varies based on tank diameter |

| Lifting Lugs | (2) lifting lugs – minimum |

| CIP | Removable CIP & fixed spray ball (180° up, 65mm) on 3” TC with 1½” TC line down to working height |

| Vent Line | Only on tanks larger than 60HL

1½” or 2” TC vent line from top head to working height |

| Sidewall | thickness & size varies based on tank size |

| Bottom Cone | 55° to 60° cone angle, 2” knuckle radius to cone – thickness varies based on tank size |

| Cooling Jacket | on sidewall and bottom cone – number of zones determined by tank size

Maximum “20” psi working pressure, 1” to 1½” FNPT inlet / outlet |

| Thermowell | (2)½” FNPT 10” thermowells |

| PRV | (1) 1½” to 2” TC Vacuum Pressure relief valve on top head or vent line tee. |

| Legs | 4-5 pipe legs depending on tank size including bracing and adjustable feet |

| Insulation | 2” insulation on sidewall and bottom cone only – minimum R12 value |

| Cladding | All welded 14 gauge cladding on sidewall & bottom cone |

| Manway | 14” x 18” side oval in/out swing “no lip” manway

(also manufactured by Ripley Stainless Ltd) |

| Sample Valve | 1” TC RSL Sample valve |

| Drain | (1) 1½” or 2” TC butterfly valve c/w “J” pipe |

| Racking | (1) 1½” or 2” TC butterfly valve |

| Tank Material | All quality inspected 304 stainless steel alloy |

| Exterior Finish | 2B with all welds ribbon polished |

| Interior Finish | 2B with all welds TIG welded with heat stain removed |

| Tank Pressure | Maximum “14.9” psi |

Options for an Extra Charge:

- Bright exterior spin polish

- RSL 18” Swivel cone manway

- Cooling Jacket – maximum”35” psi working pressure – maximum”50” psi working pressure

- 13” x 17” side oval manway

- Sample valve options

- 1½” or 2” Butterfly valve on vent & CIP lines

- Copper banding

- Rotating sprayheads

- Interior weld finish ground and polished to 120 grit

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication.

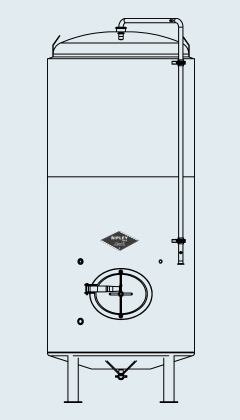

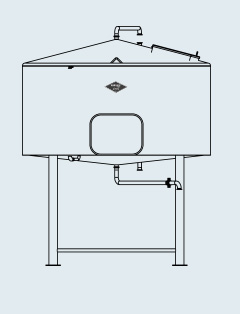

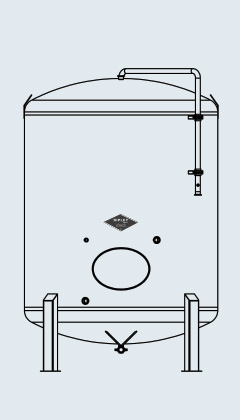

Brite Tank

Our Brite tanks are used by some brewers to carbonate the beer while others use it for storing the finished beer just prior to bottling.

| Dimensions | to be determined by RSL and customer |

| Top Head | ASME dished head (gauge varies based on tank diameter |

| Lifting Lugs | (2) lifting lugs – minimum |

| CIP | Removable CIP & fixed spray ball (180° up, 65mm) on 3” TC with 1½” TC line down to working height |

| Vent Line | Only on tanks larger than 60HL

1½” or 2” TC vent line from top head to working height |

| Sidewall | thickness & size varies based on tank size |

| Cooling Jacket | on sidewall and bottom cone – number of zones determined by tank size

Maximum “20” psi working pressure, 1” to 1½” FNPT inlet / outlet |

| PRV | (1) 1½” to 2” TC Vacuum Pressure relief valve on top head or vent line tee. |

| Legs | 4-5 pipe legs depending on tank size including bracing and adjustable feet |

| Thermowell | (2)½” FNPT 10” thermowells |

| Manway | 14” x 18” side oval in/out swing “no lip” manway

(also manufactured by Ripley Stainless Ltd) |

| Sight Tube | ¾” clear plastic hose – no valves included |

| Sample Valve | 1” TC RSL Sample valve |

| Drain | (1) 1½” or 2” TC butterfly valve c/w “J” pipe |

| Fitting | (1) 1½” TC carbstone fitting (carbstone not included) |

| Tank Material | All quality inspected 304 stainless steel alloy |

| Exterior Finish | 2B with all welds ribbon polished |

| Interior Finish | 2B with all welds TIG welded with heat stain removed |

| Tank Pressure | Maximum “14.9” psi |

Options for an Extra Charge:

- Bright exterior spin polish

- Cooling Jacket – maximum”35” psi working pressure – maximum”50” psi working pressure

- 13” x 17” side oval manway

- Carbstone options

- Sample valve options

- Vent line options

- 1½” or 2” Butterfly valve on vent & CIP lines

- Rotating sprayheads

- Interior weld finish ground and polished to 120 grit

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication

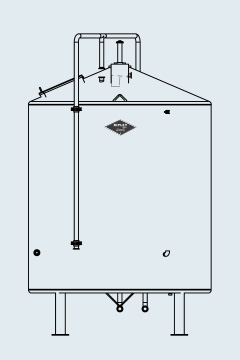

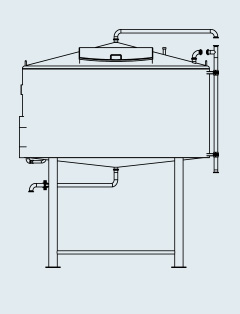

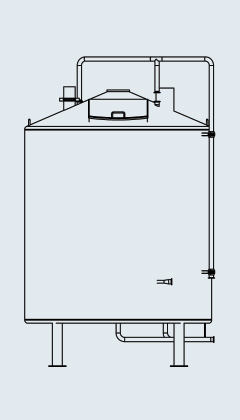

Mash Tun/ Mixer Tank

Mash Tun, Mixer tank is also known as a Mash Tank.

Primarily used for beer, mixing crushed grain and hot water. As are all of Ripley Stainless tanks, these are made to your specs.

| Type | (2) Vessel Brewhouse Systems |

| Capacities | 10HL – 30HL |

| Dimensions | To be determined by RSL & Customer

Top: 12 gauge cone, certified 304, 2B stainless steel alloy 1½” TC CIP with, (2) sprayballs, 6” dia. vent stack with condensate ring x 10’ tall with china top, 16” x 20” rectangular opening and lid – no seal 30 RPM, 2-3hp motor & drive unit for hand lifting mixer paddles All inside welds are TIG welded with heat stain removed |

| Sidewall | 14 gauge sidewall, certified 304, 2B stainless steel alloy

Steam heating jacket in (2) zones – Maximum “15” psi working pressure 1½” x 1” Whirlpool inlet 10” long thermowell, ½” NPT ¾” HD sight gauge tubing for volume level 2” insulation 14 gauge stainless steel all welded cladding, #4 spin polish finish All inside welds are TIG welded with heat stain removed |

| Bottom | 12 gauge cone, certified 304, 2B stainless steel alloy

1½” TC drain 14 gauge stainless steel all welded cladding, 2B finish (4) Stainless steel legs with adjustable feet All inside welds are TIG welded with heat stain removed 2 |

| Stainless Steel Working Platform

Dimensions |

to be determined by RSL & Customer

Approximately 4’ between (2) vessels Approximately 3’ high c/w railing and stairs Bolted to tanks Fiberglass decking All 304, 2B stainless steel framework construction |

| Swing Link Panel | Mounted in front of stainless steel platform

(9) outlets and (1) pump mount (pump not included) 1½” tubing with DIN 40 unions on face of swing link panel All other not regularly used fittings are 1½” TC |

| Piping – For complete (2) Vessel Brewhouse System | 1½” sanitary tubing connects Swing Link Panel to tanks

(7) 1½ TC butterfly valves Connections for Heat exchanger & pump TC unions are also provided so that Brewhouse can be disassembled for shipping & installation (1) 1½” TC butterfly valve behind swing link panel for tangential inlet to Brew Kettle |

*Valves not included

The Ripley Stainless Standard (2) Vessel Brewhouse system is so unique that you could add a third vessel to reduce your brew turn over time.

To plan for the third vessel we can also provide (4) extra ports in the Swing Link Panel, a second pump, provisions in the electrical panel and adjust the platform to accommodate the third tank.

Options for an Extra Charge:

- 1½ or 3 HP pump with VFD x 1½” TC fitting

- Heat Exchanger for 10-25HL system (Off shore & USA models available)

- Stainless Steel Electrical Control Panel – Brewhouse

- Stainless Steel Electrical Control Panel – Fermentation Tanks

- Butterfly Valves

- DIN Fittings

- Stainless steel pump cart

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication.

Lauter Tun

As with all of our tanks, fermentation tanks are made to your specs.

| Dimensions | to be determined by RSL and customer |

| Top | 12 gauge cone, certified 304, 2B stainless steel alloy

1½” TC CIP (3) sparging nozzles on 1” pipe ring x 1½” TC 18” x 30” rectangular opening and lid – no seal All inside welds are TIG welded with heat stain removed |

| Sidewall | 14 gauge sidewall, certified 304, 2B stainless steel alloy

¾” NPT fitting for level 4” grain inlet & slide gate 16” x 20” side rectangular manway for spent grain 2” insulation 14 gauge stainless steel all welded cladding, #4 spin polish finish All inside welds are TIG welded with heat stain removed |

| Bottom | 12 gauge slight cone, certified 304, 2B stainless steel alloy

1½” TC drain 2” insulation 14 gauge stainless steel all welded cladding, 2B finish (3-4 pcs.) .7mm wedge wire false bottom plate (4) Stainless steel legs with adjustable feet All inside welds are TIG welded with heat stain removed |

| Stainless Steel Working Platform

Dimensions |

to be determined by RSL & Customer

Approximately 4’ between (2) vessels Approximately 3’ high c/w railing and stairs Bolted to tanks Fiberglass decking All 304, 2B stainless steel framework construction |

| Swing Link Panel | Mounted in front of stainless steel platform

(9) outlets and (1) pump mount (pump not included) 1½” tubing with DIN 40 unions on face of swing link panel All other not regularly used fittings are 1½” TC |

| Piping – For complete (2) Vessel Brewhouse System | 1½” sanitary tubing connects Swing Link Panel to tanks

(7) 1½” TC butterfly valves Connections for Heat exchanger & pump TC unions are also provided so that Brewhouse can be disassembled for shipping & installation (1) 1½” TC butterfly valve behind swing link panel for tangential inlet to Brew Kettle |

The Ripley Stainless Standard (2) Vessel Brewhouse system is so unique that you could add a third vessel to reduce your brew turn over time.

To plan for the third vessel we can also provide (4) extra ports in the Swing Link Panel, a second pump, provisions in the electrical panel and adjust the platform to accommodate the third tank.

Options for an Extra Charge:

- 1½ or 3 HP pump with VFD x 1½” TC fitting

- Heat Exchanger for 10-25HL system (Off shore & USA models available)

- Stainless Steel Electrical Control Panel – Brewhouse

- Stainless Steel Electrical Control Panel – Fermentation Tanks

- Butterfly Valves

- DIN Fittings

- Stainless steel pump cart

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication.

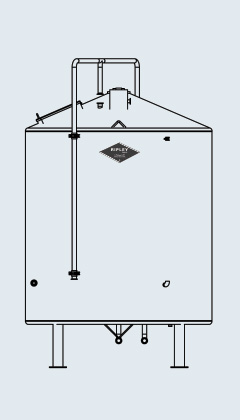

Brew Kettle/ Whirlpool

Ripley’s Brew Kettle is used for boiling the wort after the mashing process before fermentation.

| Dimensions | to be determined by RSL and customer |

| Top | 12 gauge cone, certified 304, 2B stainless steel alloy

1½ TC CIP with, (2) sprayballs, 6” dia. vent stack with condensate ring x 10’ tall with china top, 16” x 20” rectangular opening and lid – no seal All inside welds are TIG welded with heat stain removed |

| Sidewall | 14 gauge sidewall, certified 304, 2B stainless steel alloy

Steam heating jacket in (2) zones – Maximum “15” psi working pressure 1½” x 1” Whirlpool inlet 10” long thermowell, ½” NPT ¾” HD sight gauge tubing for volume level 2” insulation 14 gauge stainless steel all welded cladding, #4 spin polish finish All inside welds are TIG welded with heat stain removed |

| Bottom | 12 gauge cone, certified 304, 2B stainless steel alloy

1½” TC drain 2” insulation 14 gauge stainless steel all welded cladding, 2B finish (4) Stainless steel legs with adjustable feet All inside welds are TIG welded with heat stain removed* |

| Swing Link Panel | Mounted in front of stainless steel platform

(9) outlets and (1) pump mount (pump not included) 1½” tubing with DIN 40 unions on face of swing link panel – All other not regularly used fittings are 1½” TC |

| Piping – For complete (2) Vessel Brewhouse System | 1½” sanitary tubing connects Swing Link Panel to tanks(7)

1½” TC butterfly valvesConnections for Heat exchanger & pump TC unions are also provided so that Brewhouse can be disassembled for shipping & installation(1) 1½” TC butterfly valve behind swing link panel for tangential inlet to Brew Kettle |

The Ripley Stainless Standard (2) Vessel Brewhouse system is so unique that you could add a third vessel to reduce your brew turn over time.

To plan for the third vessel we can also provide (4) extra ports in the Swing Link Panel, a second pump, provisions in the electrical panel and adjust the platform to accommodate the third tank.

Options for an Extra Charge:

- 1½ HP pump with VFD x 1½” TC fittingHeat Exchanger for 10-25HL system (Offshore & USA models available)

- Stainless Steel Electrical Control Panel

- BrewhouseStainless Steel Electrical Control Panel

- Fermentation Tanks

- Butterfly ValvesDIN Fittings

- Stainless steel pump cart

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication.

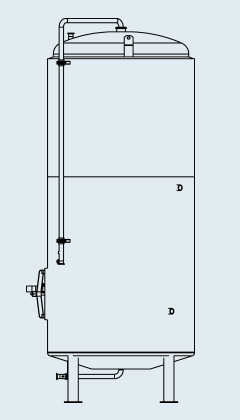

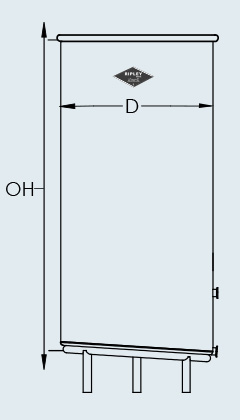

Single Wall Conditioning Tank

These stainless steel Conditioning tanks are designed specifically to aid in the aging of the beer and are used for storage in a cold room.

| Dimensions | to be determined by RSL and customer |

| Heads | ASME flanged & dished top and bottom heads (thickness varies based on tank diameter) |

| Lifting Lugs | (2) lifting lugs – minimum |

| CIP | 1½” CIP & side arm complete with 1½” butterfly valve spray ball and removable spray ball (180° up, 65mm) |

| Sidewall | thickness & size varies based on tank size |

| PRV | (1) 1½” TC Vacuum Pressure relief valve on top head |

| Legs | (3) or (4) channel legs – non adjustable |

| Manway | 12” x 17” side oval, in/out swing manway |

| Sample Valve | (1) 1½” TC Sample valve |

| Drain | (1) 1½” TC butterfly valve complete with “J” pipe |

| Fitting | (2) 1½” TC on sidewall |

| Tank Material | All quality inspected 304 stainless steel alloy |

| Exterior Finish | 2B with all welds ribbon polished |

| Interior Finish | 2B with all welds TIG welded with heat stain removed |

| Tank Pressure | Maximum “14.9” psi |

Options for an Extra Charge:

- Bright exterior spin polish

- Cooling Jacket – maximum “35” psi working pressure

- Maximum “50” psi working pressure

- 14” x 18” side oval manway

- Sample valve options

- Adjustable feet

- 1½” TC carbonation stone

All tanks are fabricated using standard material sizes and normal beer tank dimensions.

Ripley Stainless Ltd. is a custom tank fabricator and can design and fabricate tanks to suit your specific requirements. Shop drawings must be approved prior to fabrication.

Hot and Cold Liquor Tanks

Ripley designed these tanks a number of years ago, for the purpose of heating or cooling beer. These are hardy tanks and are super functional.

| Dimensions | Cylindrical – to be determined by RSL and the customer |

| Top Head | Top 1/3 hinged lid |

| Lifting Lugs | (2) lifting lugs – minimum |

| Sidewall | Thickness & size varies based on tank size |

| Heating Source | Internal heating coil |

| Legs | 12” tall legs |

| Fitting | Includes 1½” TC drain, sight ¾” clear plastic tubing |

| Tank Material | All 316, 2B stainless steel alloy |

| Exterior Finish | Insulated with Mineral Wool with white paint standard finish |

| Optional Exterior Finish | 14 gauge stainless steel all welded cladding |

Cold Liquor Tank

| Dimensions | Cylindrical – to be determined by RSL and the customer |

| Top Head | Top 1/3 hinged lid |

| Lifting Lugs | (2) lifting lugs – minimum |

| Sidewall | Thickness & size varies based on tank size |

| Cooling Source | Internal cooling coil |

| Legs | 12” tall legs |

| Fitting | Includes 1½” TC drain, sight ¾” clear plastic tubing |

| Tank Material | All 304, 2B stainless steel alloy |

| Exterior Finish | Insulated with polyurethane with white paint standard finish |

| Optional Exterior Finish | 14 gauge stainless steel all welded cladding |